What are fire dampers?

Fire dampers are part of a building fire safety system, designed to prevent the passage of fire through a compartment wall or floor. Fire dampers form part of a building ventilation system and are installed where air handling ducts pass through fire-separating elements such as compartment walls or enclosures protecting escape routes.

Typically, a fire damper is a metal curtain within a duct held up by a thermal element (referred to as a fusible link) and released in the event of a rise in temperature. The thermal element will melt at a set temperature releasing a spring-operated metal curtain, which is pulled down to fill the opening the duct passes through, preventing the passage of fire.

Smoke dampers are automatically operated once triggered by smoke detectors. The smoke damper will open or close to prevent or allow the passage of smoke.

Fire and smoke dampers are key to the control and containment of fire in the event of an emergency. By providing a barrier which fire and smoke cannot pass, these assets play a critical role in the fire safety system within any building.

Why do fire dampers need to be tested?

All fire safety systems must be maintained in an efficient and effective state. Fire and smoke dampers form part of the fire compartmentation system to contain and control the spread of fire through a building.

Fire dampers are subjected to constant air flow through the building ventilation system. Routine inspection is required to check for signs of corrosion, obstruction, or accumulation of dirt & dust, and testing is required to confirm the damper still opens and closes effectively reducing the risk of a fire compartment failing.

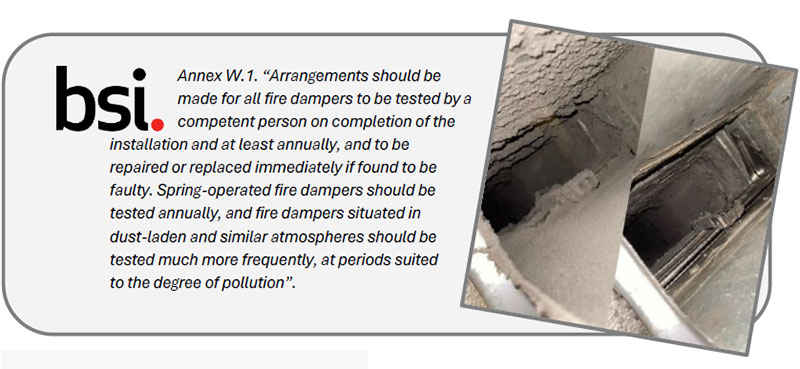

The routine inspection, testing and maintenance of fire dampers is required in accordance with Bristish Standard 9999 Annex W.1.

British Standard 9999:2017 Code of Practice for Fire Safety in the Design, Management & Use of Buildings states that:

Who is responsible?

Under The Regulatory Reform (fire safety) Order 2005 the responsibility for a facility’s fire safety system falls on the organization’s “responsible person”. Typically, that responsible person is the employer, or the owner of the facility. If you are a building manager or owner, you have a duty of care to staff, employees and visitors to provide a safe environment.

RRO 2005 states the responsible person must:

As fire damper test and inspection technicians we become a responsible duty holder of the report content which must be a truthful reflection of the fire damper(s) condition throughout a building.

All our damper inspection and testing is carried out by trained and competent individual(s). Our damper technicians will follow best of practice guidance contained within NAAD-22 [Fire Dampers] standards, and other relevant sources such as BESA DW/145 and VH001 guidance documents.

Best of practice

The National Association of Air Duct Specialists UK [NAADUK] has developed the most comprehensive guidance documents available for indoor air quality and fire damper servicing, installation, and design. Working with various other association bodies they strive to continually improve industry standards by enhancing training, development and awareness across the country for this critical fire safety system.

Other relevant laws and standards apply to the installation and maintenance of fire dampers:

What are the common problems found with fire dampers?

There are many problems that can impact the performance of a fire damper, and there are an alarming number of these issues found day-by-day.

Commons problems found include:

What should be included in a fire damper testing report?

The purpose of a testing report is to provide appropriate evidence that the fire precautions and safety systems are being maintained as required under the Regulatory Reform (fire safety) Order 2005. Should an enforcement authority request you provide records and evidence of your fire and smoke damper maintenance, the servicing report will the document you can provide. Essential provides one of the most comprehensive reports available on the market.

All testing reports will include:

How can Essential help?

No matter the current state of your fire dampers, records, or documentation available, Essential has a solution to reach fire damper compliance.

Essential operate UK wide and offers a comprehensive range of fire damper services including surveys, inspection and testing, and remedial works.

At Essential our team of operatives are trained to carry out fire and smoke damper testing to comply with BS 9999:2017. All our operatives are trained to follow BS 9999 & CITB and are members of the National Association of Air Duct Specialists UK.